BLOG

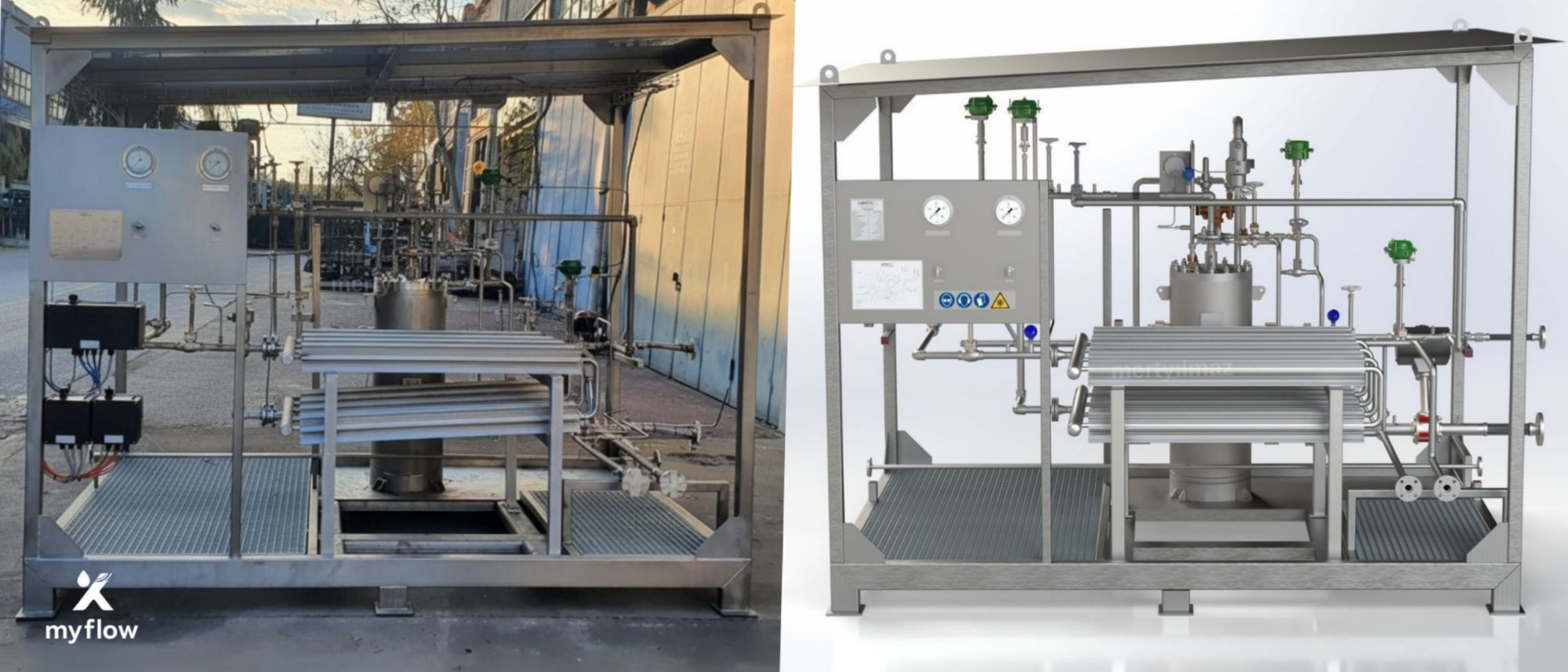

Regasification Plants

Project Description

Cryogenic regasification plants for LNG, LOX, LIN, and LAR designed for operation from −196°C to +40°C. My contribution includes arranging equipment in a compact 3D layout with clear access, sizing storage tanks according to expected consumption, and setting A.A.V. capacity to the required flow. I also instrument key pressure and temperature points and stabilize outlet pressure with properly sized regulators; the design remains PED and ATEX compliant.

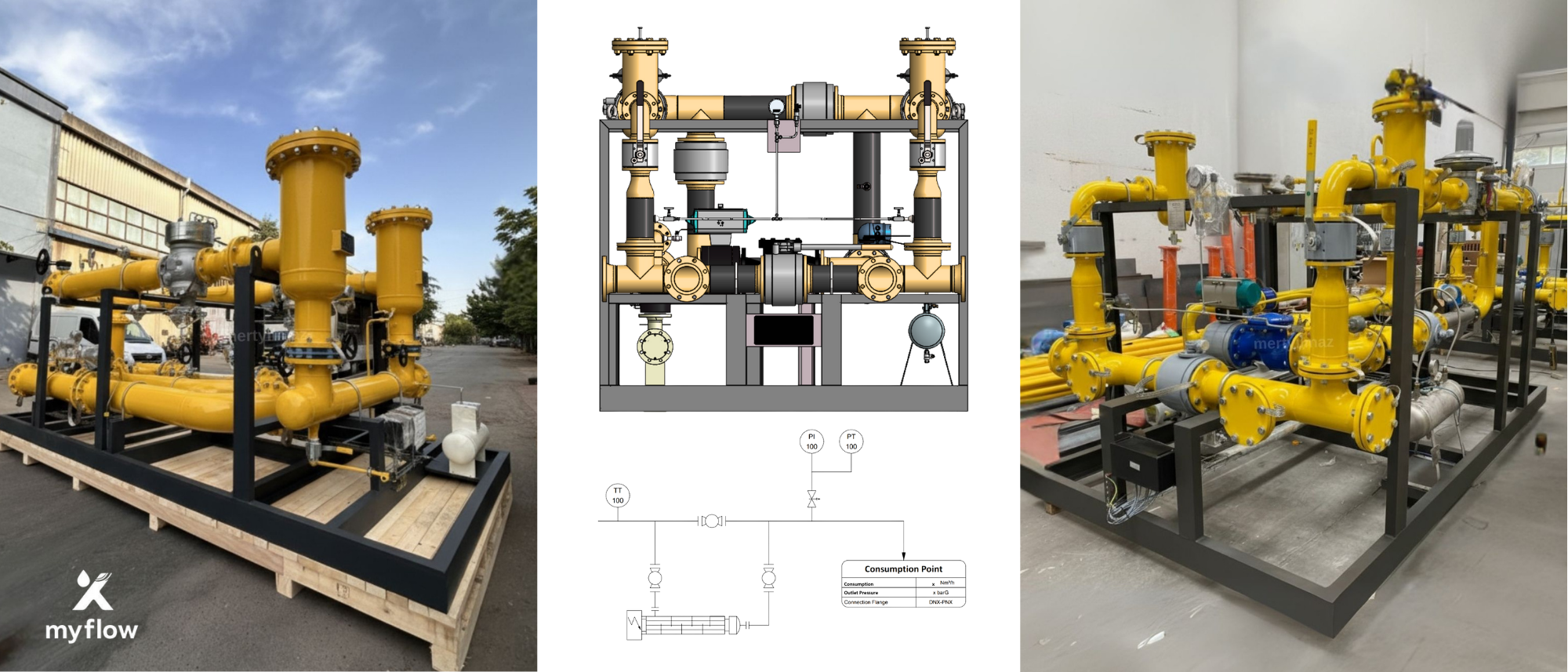

Regasification & Metering Skids

Metering & Pressure Regulation Skids (No Vaporizer)

Compact skids integrating pressure regulation and fiscal or process metering for −20°C to +50°C service. My contribution includes compact 3D skid layout design, regulator sizing, and line selection to maintain a steady outlet pressure, as well as meter selection to meet process capacity and accuracy. When ambient air temperature is insufficient to reach the outlet gas temperature setpoint, an electric trim heater is integrated into the compact package, maintaining a small footprint and single-point installation. The design remains PED and ATEX compliant.

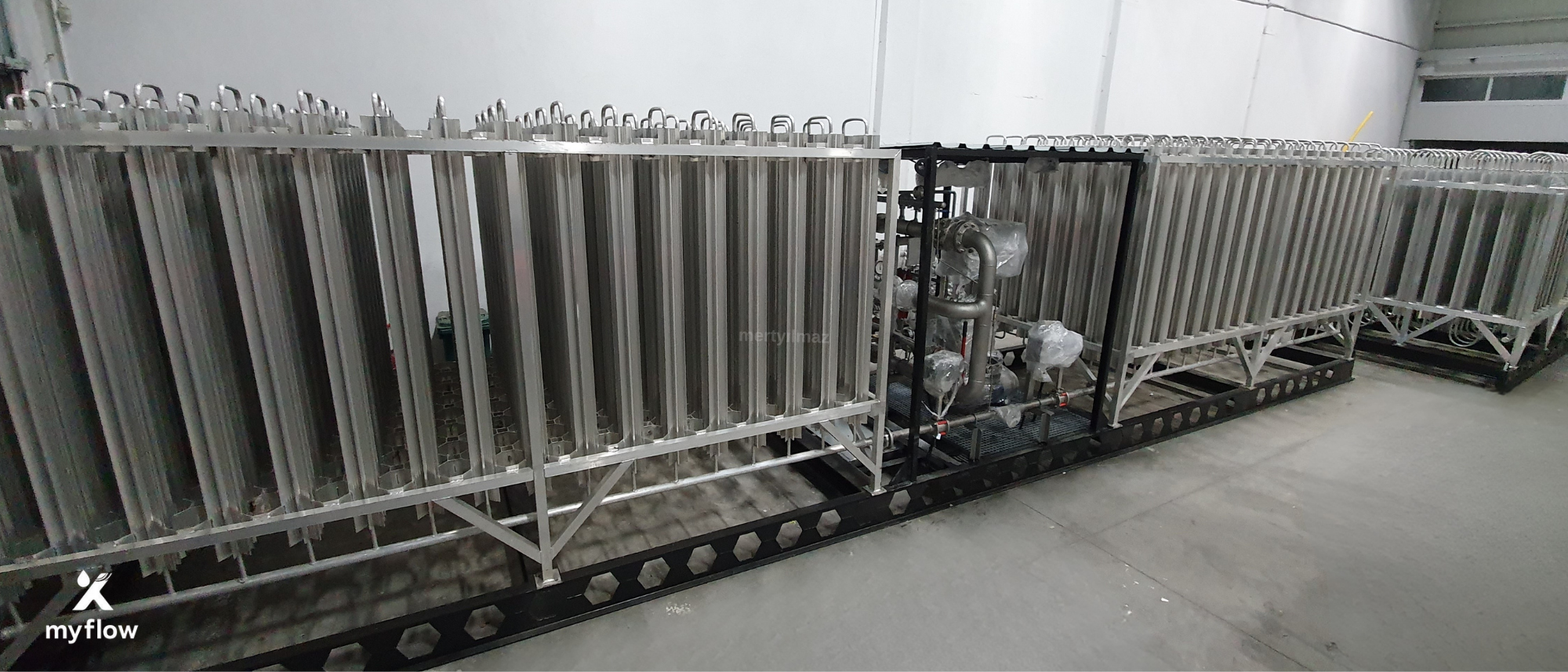

Plug and Play A.A.V. Packages (with Vaporizer)

A single-frame package combining the air ambient vaporizer (A.A.V.), pressure control, and metering for quick installation and start-up. My contribution includes packaging the A.A.V. with pressure regulation and metering, selecting regulators for stable outlet pressure, and choosing meters according to process capacity and accuracy. An electric trim heater is integrated when ambient conditions are insufficient, ensuring the outlet temperature setpoint is met without increasing the footprint. The design remains PED and ATEX compliant, and the unit ships ready for fast commissioning.

Refueling & Unloading Stations

Refueling and unloading stations for L-CNG service, covering LNG truck offloading to CNG delivery at dispensers. My contribution includes sizing the storage tank based on the customer’s consumption, arranging safety distances according to relevant standards, selecting the cryogenic pump for the required flow and pressure while avoiding cavitation, and, when CNG fueling is provided, sizing the A.A.V. to meet the delivery temperature at operating pressure to keep the process within specification.

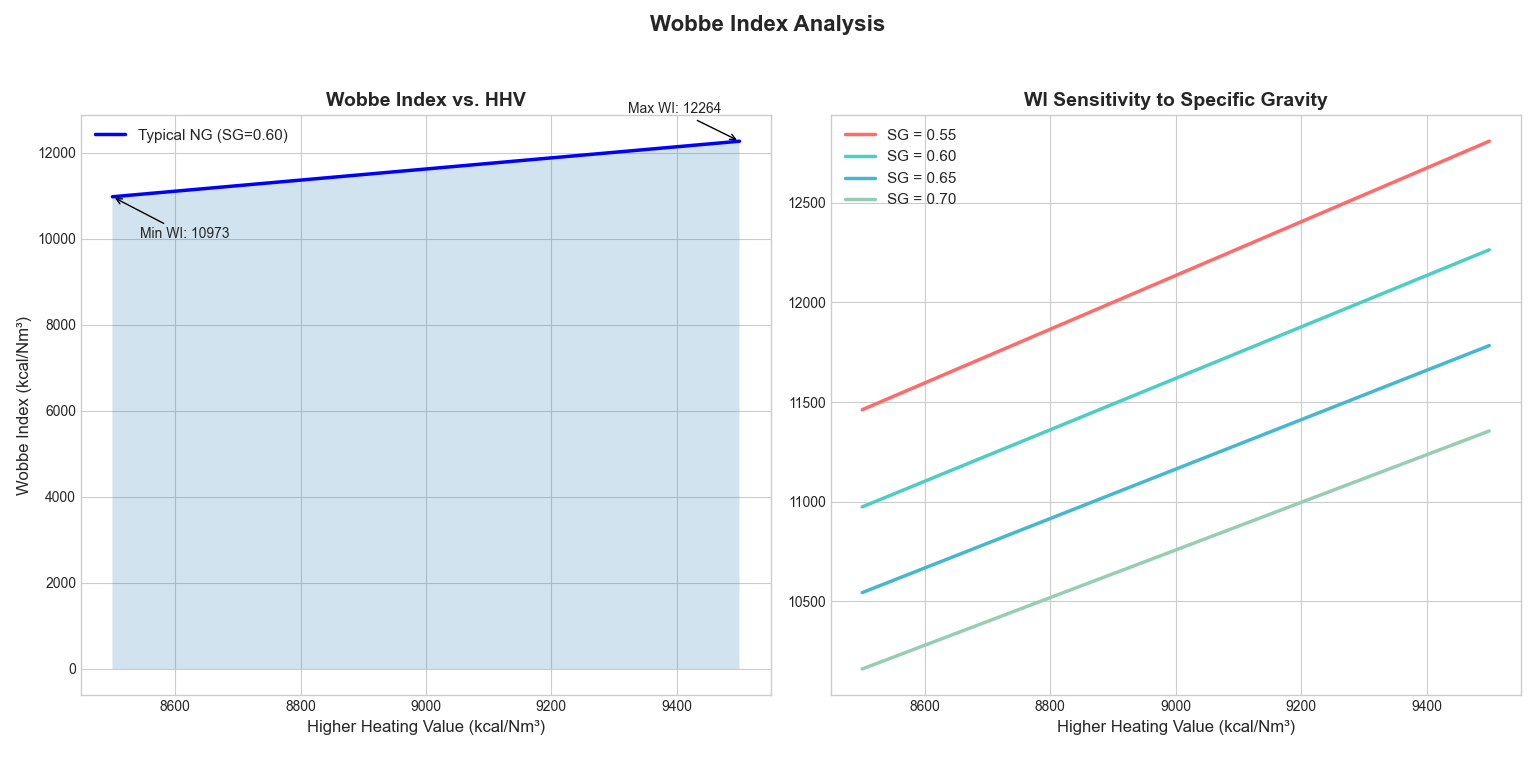

Blending Systems

We designed and produced LPG & Air-based SNG blending skids with UESTCO Energy Systems — the first SNG blender skid in Türkiye. My contribution includes calculating system requirements from the customer’s natural gas consumption, computing LPG and air ratios from composition, checking the Wobbe Index and dew point at reference conditions, and setting pressure setpoints and allowable flow ranges with process checkpoints to keep the blend on-spec. I have also worked on Hydrogen & Natural Gas blending to reduce CO₂ emissions, defining hydrogen ratios up to practical limits and evaluating their effects on the Wobbe Index and burner performance.